The finishing method used on critical parts and components for your OEM off-road projects directly affects durability, efficiency, and long-term performance. Every process decision must be made strategically to ensure your product works as expected in the field, including which grinding method you select.

Two common grinding methods are rotary surface grinding and precision grinding. Each may seem similar at a glance, but both offer distinct strengths and limitations that help determine whether your equipment will withstand the rigours of heavy-duty use in agricultural, construction, mining, and industrial applications.

In this month’s blog, we discuss rotary surface and precision grinding to help you understand how each process will affect your project.

What Is Rotary Surface Grinding?

Rotary surface grinding is used to process flat, large-area surfaces quickly and efficiently. The grinders excel at reducing substantial material in a single pass to maintain flatness across the entire workpiece.

The tool’s rotational motion provides a uniform cutting action that minimizes heat buildup and preserves material integrity, essential in heavy-duty applications where thermal distortion can compromise assembly alignment or introduce premature wear. Additionally, rotary surface grinding’s fast setup and high-volume processing scale well, eliminating bottlenecks in operations where multiple large components must be prepared for further processing and assembly.

This method is typically preferred for any component where flatness and parallelism are essential for sealing or load transfer, such as brake plates, clutch housings, hydraulic manifold faces, mounting pads, and structural plates. However, rotary surface grinding has limitations, including an inability to achieve the dimensional accuracy required for complex contours or intricate shapes. It also isn’t recommended for equipment where tight tolerances are non-negotiable. For these applications, precision grinding is the recommended solution.

What Is Precision Grinding?

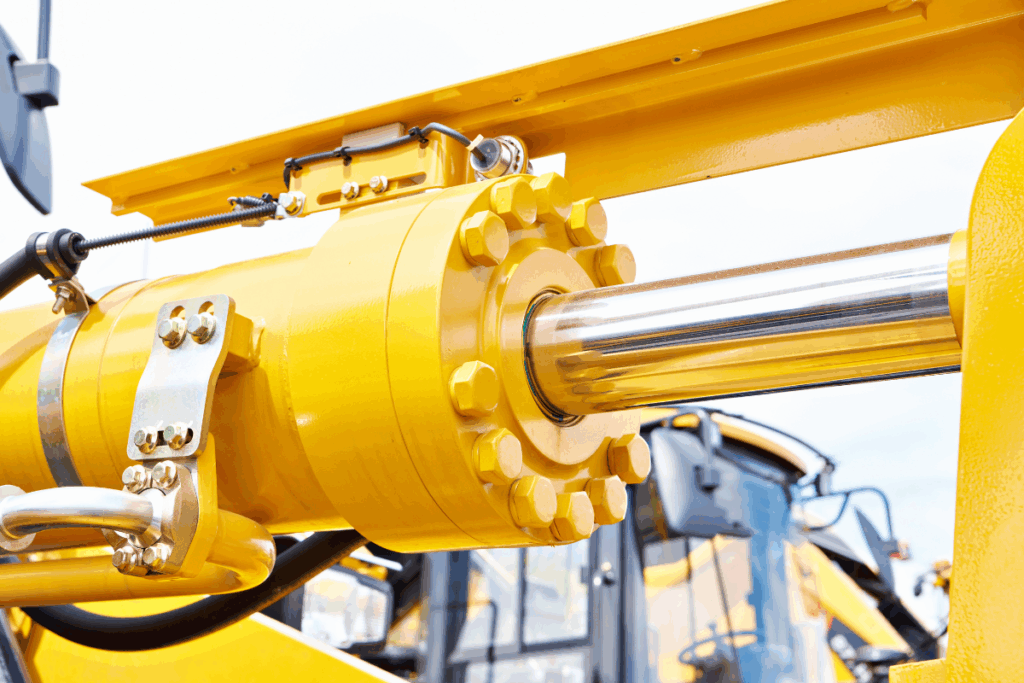

When your parts and components demand a fine surface finish, precision grinding delivers exactly what you need. Using CNC-controlled equipment and specialized wheels, precision grinding produces highly repeatable finishes down to the last micron. It is the go-to method for parts that directly affect powertrain efficiency, load transfer, or sealing integrity.

The strength of precision grinding lies in its flexibility and dimensional control, which enable it to easily process complex cylindrical, angular, contoured, and multi-axis profiles with tight tolerances. For heavy-duty components exposed to continuous shock loads, such as axles or driveline components, precision grinding provides a level of consistency that translates to better load distribution, lower vibration, and reduced wear. It can also be used for hydraulic systems where smooth performance, leak-free sealing, and tolerance stability are critical in punishing environments.

The benefits of precision grinding are offset by reduced production efficiency. This method is typically slower and requires more controlled setups that affect scheduling. However, industrial OEMs understand that the additional production time is well worth the results that precision grinding delivers.

Read More: Our Solutions

Rotary Surface Grinding Vs. Precision Grinding: Which Is Best For Your Application?

Essentially, the choice between which grinding method boils down to the following breakdowns.

Rotary surface grinding is the right choice when:

- The part is primarily flat or planar

- Large surface areas must be machined consistently

- The primary goals are parallelism, flatness, and repeatability

- Material removal needs to be efficient without ultra-fine finishes

- The component functions as a structural, mounting, or mating surface rather than a precision-motion component

Precision grinding is the better solution when:

- The part requires tight tolerances

- The shape is complex or requires cylindrical, angular, or contoured grinding

- Surface finish quality directly affects performance in the final application

- The component is part of a powertrain, hydraulic circuit, or precision-fit assembly

- Vibration reduction, efficiency, or sealing depend on accuracy

In many cases, a hybrid approach that includes both methods is used. For example, your fabricator might employ rotary grinding for initial flat preparation, followed by precision grinding for final functional surfaces.

Precision machine, fabrication, and finishing suppliers that offer both capabilities under one roof provide a significant advantage by reducing lead times, eliminating cross-vendor variation, and ensuring consistent process control. When you’re ready to explore the benefits of using a single-source supplier with the expertise, technology, and experience you need to bring your designs to life with total accuracy, get in touch with AC Fabrication & Assembly Solutions.

Read More: The Impact Of Tolerances On Fabrication Projects

AC Fabrication And Assembly Solutions: Using Advanced Metalworking Techniques To Deliver Better Quality Products

With 300 years of combined experience under our belts, we offer unparalleled quality, durability, and service that you won’t find with any other supplier. These are delivered by skilled technicians whose primary goal is to create sustainable growth for our customers.

Contact an AC Fabrication and Assembly Solutions expert at 204-952-1900 or sales@acfabandassembly.com for a custom quote on your next project today!