The Impact Of Tolerances On Fabrication Projects

Meeting quality standards for agricultural, construction, and industrial parts and equipment depends on meeting the exact design specifications for every component required in the final application.

Although there are multiple facets to consider in every metalworking project, meeting tight tolerances is becoming increasingly important to manufacturers who want to stay competitive in the marketplace.

All You Need To Know About Metal Forming And Stamping

There is a broad range of precision machining techniques used by metalworking engineers to transform raw materials into high-quality, to-spec parts and components. These processes have been honed over decades, and sometimes centuries, so modern fabrication production facilities can deliver products that bring virtually any dream design into reality.

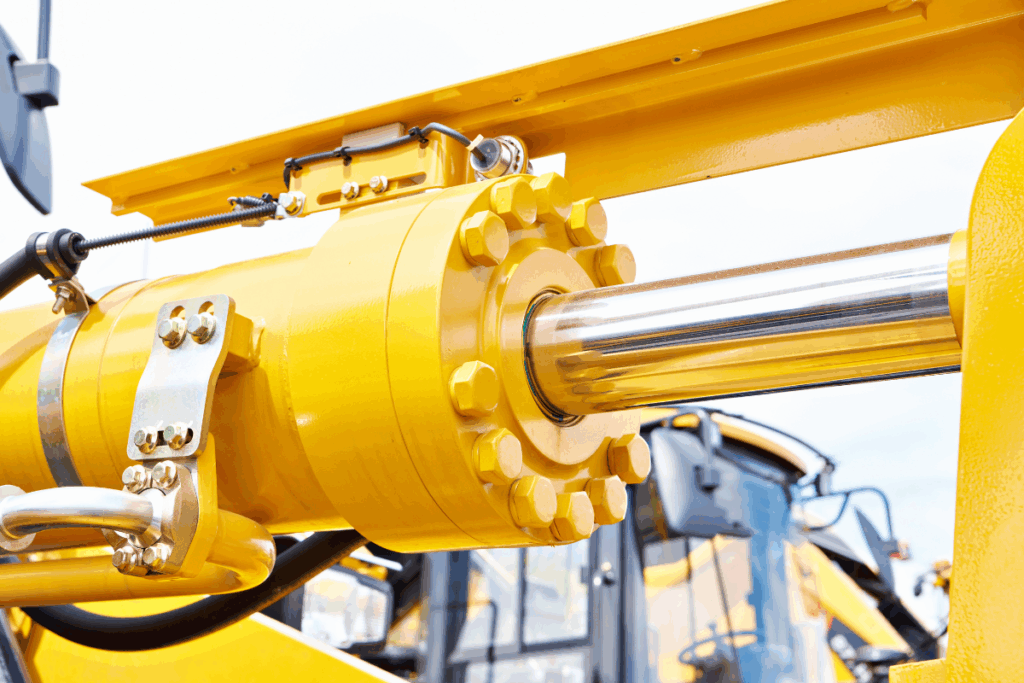

Special Considerations For Fabricating Hydraulic Cylinders

Hydraulic cylinders are critical components for heavy-duty off-road vehicle applications in the agricultural, mining, construction, and other industries where performance, durability, and quality are paramount.

In this month’s blog, we’ll look at the unique design and fabrication characteristics of these critical components so our customers can get a deeper understanding of the attention to detail that goes into every project.

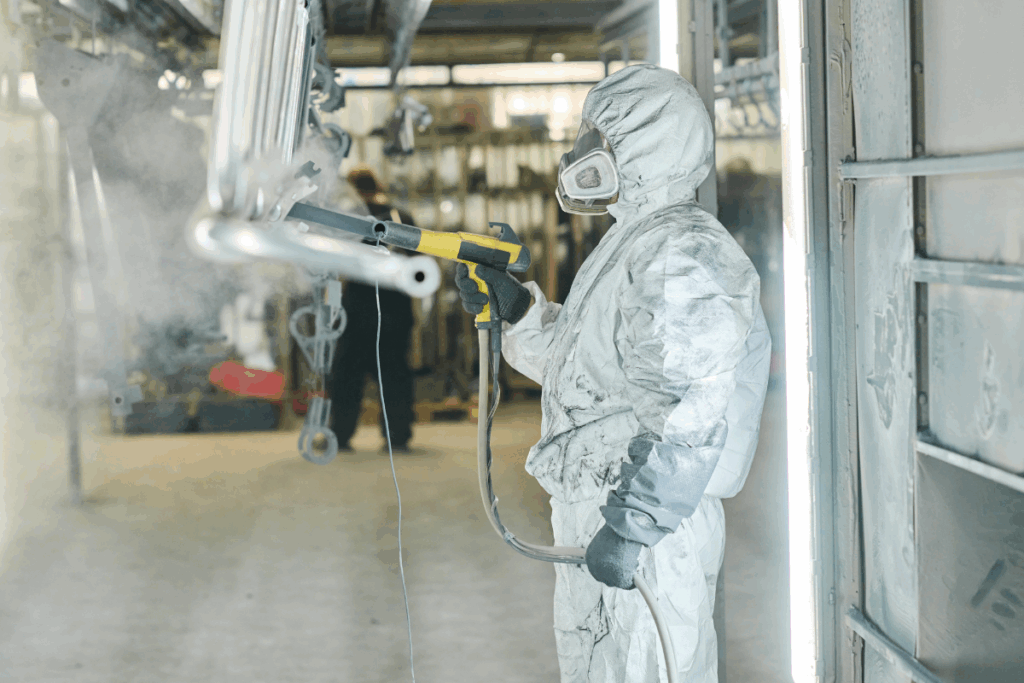

Five Key Benefits Of Applying Powder Coating To Your Precision Machine Products

Advanced coatings play a significant role in enhancing a finished part’s durability, performance, and aesthetics while protecting it from premature wear that results from friction, abrasion, or impact in everyday use.

Powder coatings are a type of advanced coating increasing in popularity with off-road vehicle manufacturers as they offer the end user a polished appearance and enhanced resistance to chemicals, moisture, and other corrosive elements that can damage parts and shorten their lifespan.

Industry 4.0: Transforming The Precision Machining Industry For The Better

Over the last several centuries, industrial revolutions have transformed how manufacturers build things. From steam-based manufacturing machines to mass-production assembly lines, our industry has thrived on innovation, making the manufacturing process more efficient while enhancing the quality of fabricated goods.

What’s The Difference Between MIG And TIG Welding?

Forward-thinking off-road OEMs recognize that their products must be constructed using advanced fabrication techniques to achieve the highest quality results. At AC Fabrication & Assembly Solutions, we ensure that we recommend precision machining processes that are completely aligned with our customers’ design specifications and the final product’s application.

Welding is one process that plays a critical role in the fabrication success of most construction and agricultural components. Strong joins between metal parts used in harsh industrial applications are vital to ensure product quality, durability, and reliability during regular use.

How To Manage The Costs Of Your Metalworking Projects

Manufacturers are constantly balancing rising costs with tighter budgets, making cost management more crucial than ever. This also means they frequently face the challenge of finding innovative and effective ways to optimize their project investments while maintaining high standards of quality and performance in their products.

As a premier construction and agriculture equipment manufacturing company, we’ve collaborated closely with our global OEM customers to manage their project costs. Here are five of our top recommendations for cost-conscious manufacturers seeking fresh ideas on getting the best results from their production budget.

How Fostering A Culture Of Continuous Improvement Supports Business Growth

As a company with long roots in metalworking, we understand the importance of change to ensure long-term stability and success.

However, we believe that change doesn’t come in spurts or when a new piece of technology is introduced. Change needs to be rooted in a continuous improvement strategy to help transformations go smoothly and ensure customers reap the benefits of the changes.

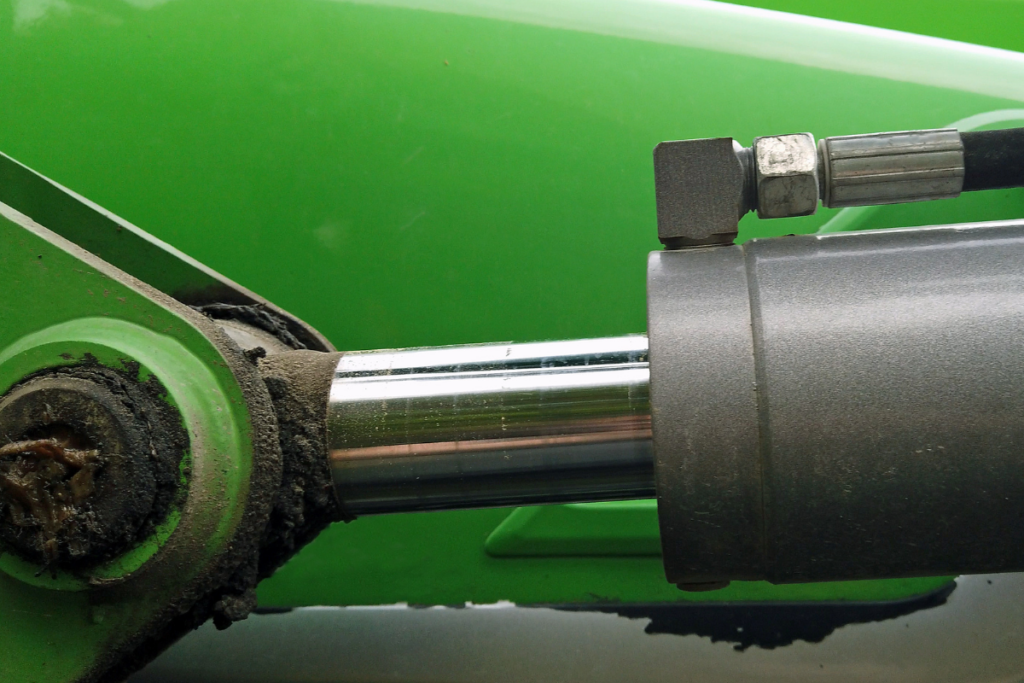

Skiving And Roller Burnishing’s Role In Precision Machining

Modern manufacturers expect nothing less than the highest-quality parts and components from their precision machine suppliers. With the tech-based metalworking capabilities available today, there’s simply no reason to expect anything less.

At AC Fabrication & Assembly Solutions, one of the world’s most trusted off-road construction and agriculture equipment manufacturing companies, we use advanced techniques throughout the manufacturing process, including finishing, during which skiving and roller burnishing come to the fore.

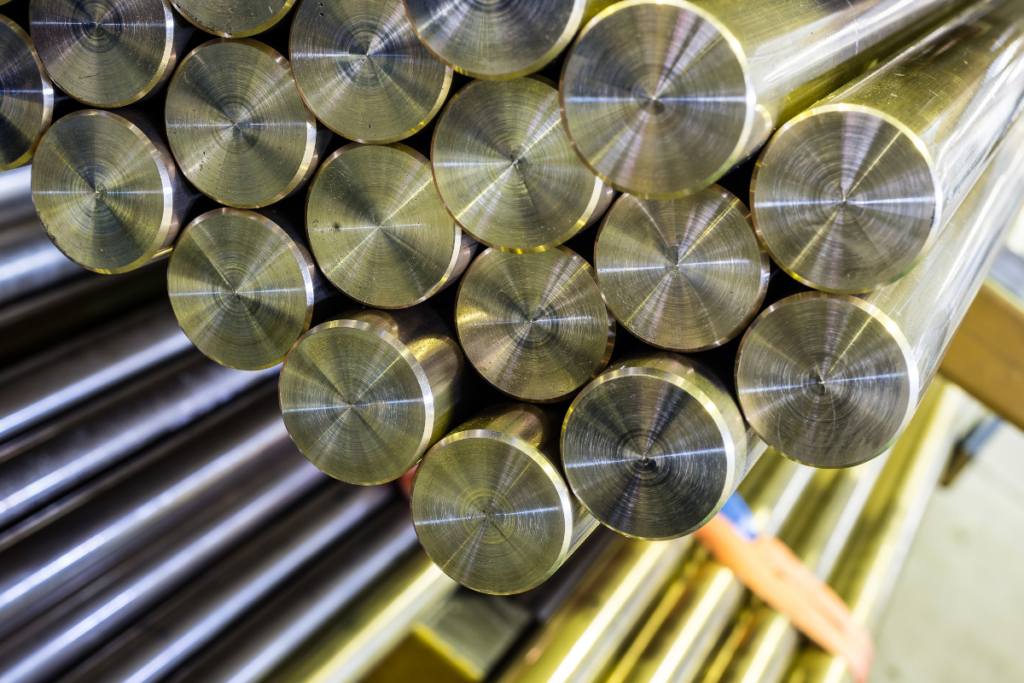

How To Select The Right Material For Your Metalworking Projects

Off-road vehicles for agricultural, construction, mining, and other applications work under extreme industrial conditions. Their durability requires solid, reliable fabrication using the right materials for its various parts and components.

With all the different metals and specialty alloys available for fabrication, off-road equipment manufacturers might not be sure which materials are best to use in each component.