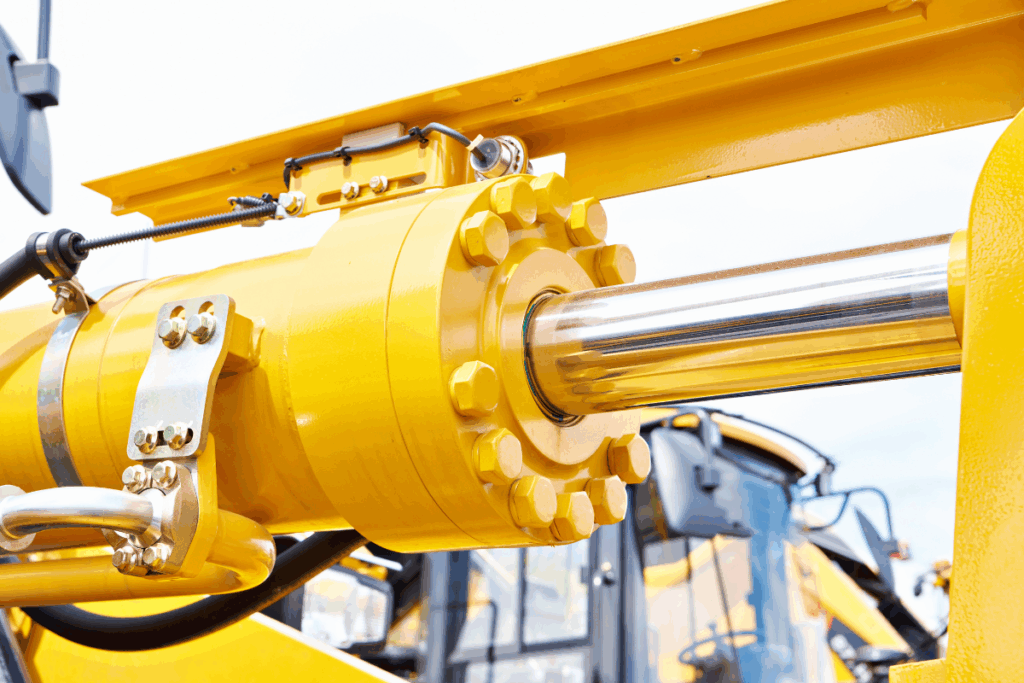

Meeting quality standards for agricultural, construction, and industrial parts and equipment depends on meeting the exact design specifications for every component required in the final application.

Although there are multiple facets to consider in every metalworking project, meeting tight tolerances is becoming increasingly important to manufacturers who want to stay competitive in the marketplace.

At AC Fabrication & Assembly Solutions, we recognize the importance of achieving tight tolerances to ensure product quality, especially with complex or intricate designs where fitting into the final assembly is non-negotiable.

On this month’s blog, we’ll take a look at the different types of tolerances in metalworking and discuss their impact on the metalworking process.

The Critical Role Of Tolerances In Precision Machining

Before diving into the topic, let’s define what tolerance refers to in metalworking.

Tolerance is the amount by which a precision-machined component can deviate from its original design specification. Meeting tolerance thresholds is crucial because it affects how the individual pieces in an assembly fit together, thereby impacting the accuracy of the finished product as a whole.

Every aspect of the fabricated part is subject to at least one type of tolerance. One example is geometric tolerances, which affect the flatness, roundness, perpendicularity, and other elements of the part’s shape. Linear tolerances, such as length, width, or thickness, must also be considered.

In metalworking, there are generally three main types of tolerances:

- Limit tolerances, which are two-dimensional values that specify the acceptable range of a dimension

- Unilateral tolerances that permit only one direction of variation from the specified dimension

- Bilateral tolerances that ensure that the upper and lower limits deviate from the base dimension are symmetrical

Tolerances in metalworking are measured using a variety of precision instruments and techniques, ranging from basic handheld tools to advanced computer-controlled systems.

Parts that demand extreme precision have very tight tolerances. Achieving these tolerances requires specialized fabrication methods that take time to complete. Other non-critical parts of a project can have wider tolerances that don’t require specialized processes, allowing manufacturers to optimize their project spend when possible.

Read More: Industry 4.0 – Transforming The Precision Machining Industry For Better

What Is Geometric Dimensioning And Tolerancing (GD&T)?

You have likely heard of GD&T, but you may not be aware of what it means and why it’s essential to understand its value in precision machining.

GD&T is a system that defines tolerances in the design, with numeric call-outs beside the dimensions to which they apply. It goes beyond other systems, such as standard dimensioning and tolerancing (SD&T), which only provide the dimension and tolerance of a part, to include detailed geometric characteristics such as flatness, position, and concentricity.

These values are critical to ensuring that every aspect of the finished components meets the required tolerances, thereby improving the quality of the final assembly.

How Do Tolerances Affect The Precision Of A Machine Process?

Tolerance considerations are incorporated into the manufacturing process, starting with selecting materials that meet the required tolerance levels. Steel is typically the preferred material for tight tolerances due to its strength and hardness. Softer materials, such as aluminum, may exhibit greater variation due to heat or deformation during fabrication, affecting their ability to meet tighter tolerance requirements.

As mentioned, meeting exact tolerances often requires specialized equipment, such as CNC machining. CNC technology offers a wide range of benefits to manufacturers, but it can also affect your budget. For example, complex parts with tight tolerances often require careful programming, tool calibration, custom tooling, and additional finishing processes such as grinding or polishing. Enhanced quality control measures are also undertaken to ensure tolerances are correct.

Although this heightened attention to detail can increase production costs, most construction, industrial, and agricultural manufacturers recognize that the investment is well worth it to elevate the quality of the final result.

When a part doesn’t require tight tolerances, fabricators can use a broader range of metalworking techniques, such as stamping or plasma cutting, to help optimize costs.

However, before the process begins, you must determine the exact tolerance required by your parts. This complex process can be made easier by partnering with an experienced precision machine supplier that can deliver the results your project deserves.

If your current service provider can’t do that for you, give AC Fabrication & Assembly Solutions a call.

Read More: Our Solutions

Partner with AC Fabrication & Assembly Solutions: Your Premier Manufacturing Supplier Of Agricultural, Construction, And Industrial Equipment Components

AC Fabrication & Assembly Solutions’ engineers will collaborate with you to determine exact tolerances for each part. We’ll also help identify non-critical areas where tolerance requirements can be slightly relaxed, uncovering multiple cost-saving opportunities without compromising the end product’s quality.

With AC Fabrication in your corner, you can be assured of quality products and exceptional customer service focused solely on the successful completion of your project, even when you need the tightest tolerances for complex, intricate parts and equipment.

AC Fabrication And Assembly Solutions: Using Advanced Metalworking Techniques To Deliver Better Quality Products

With 300 years of combined experience under our belts, we offer unparalleled quality, durability, and service that you won’t find with any other supplier. These are delivered by skilled technicians whose primary goal is to create sustainable growth for our customers.

Contact an AC Fabrication and Assembly Solutions expert at 204-952-1900 or sales@acfabandassembly.com for a custom quote on your next project today!